CYCLE

The flavour and quality of the coffee that we find in a cup is built step by step through various stages.

The varieties we use are selected exclusively from tropical plantations in South America and Africa. We start with extremely high-quality raw materials.

The beating heart of the production is the coffee roasting machine used by the master roaster to control the roasting curve: monitored constant temperature and the right roasting point to achieve what we love to find in the cup.

The recipes for the blends have been expertly refined over the years to encapsulate that acquired know-how which is a secret perceived with the senses.

Custom roasting

Everyone has their own unique way of enjoying coffee. That’s why we use separate roasting processes. Each coffee variety has its own roasting.

This is where the skills and sensibility of the master roaster come in, to reveal the aroma, structure and flavour of the coffee.

We have different roasting machines and different methods, such as:

• a traditional technique that uses conduction for the classic blends, with machines that have by now become rare

the convection method is used for the more modern blends.

The delicate cooling and degassing phase

After roasting, the blend must cool and release part of the carbon dioxide that is naturally found in coffee. This is a very delicate phase.

This is where the volume, hardness and colour of the beans emerge and the aromatic substances in the coffee are condensed. The correct degassing is responsible for the creamy consistence that we find in a cup of espresso.

In short, after degassing, the roasted coffee in the silos is used to create the blend, whose recipe remains a secret, the result of the skill of the roaster.

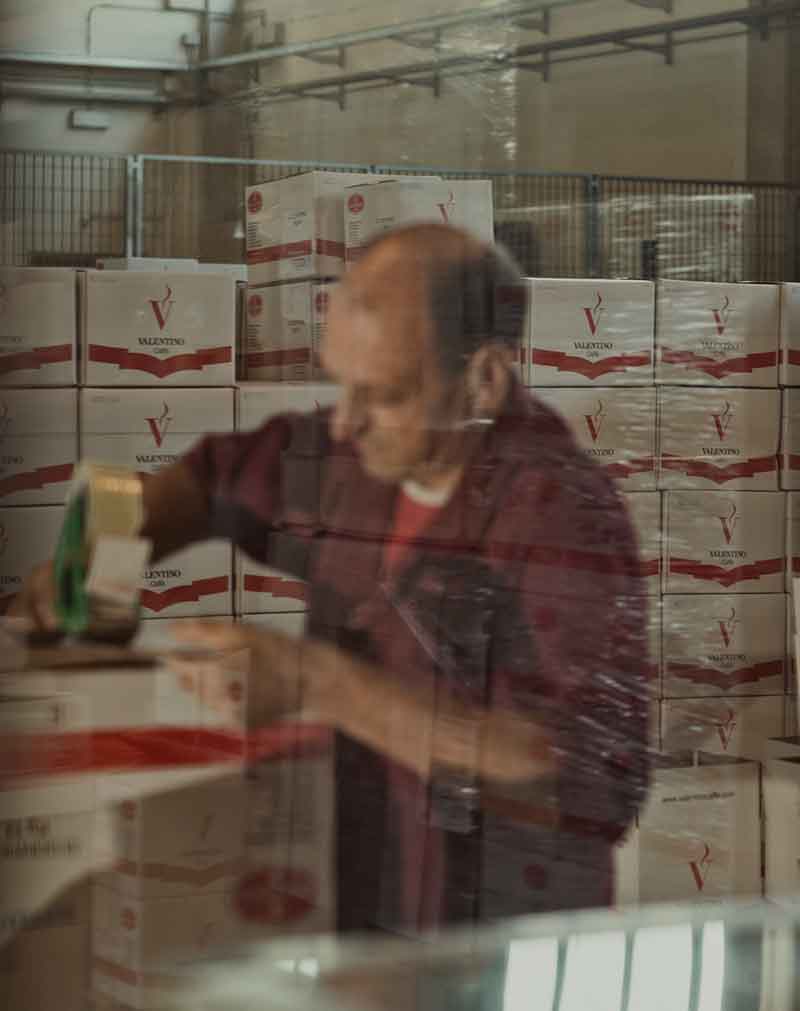

Packaging

This maintains the freshness of the coffee and increases its life.

Coffee pods

The single-serve pods are one of Valentino Caffè’s leading products. Here too the modified atmosphere and nitrogen flushing, with a pod packing machine, allows us to produce a coffee that remains fresh, as if it had been freshly ground. The pods are packaged in cases of various sizes, based on the quantity.

Organic coffee

An organically certified (ICEA) line of coffee with separate roasting, grounding and packaging.

Specialty Coffee

The specialty coffees are extremely high-quality green coffees produced in limited quantities. This is a concept that dates back to the seventies, and which has gained in popularity once again. Different coffees are produced in special climate and environmental conditions, with particular attention to all the stages of the production process, to achieve a distinctive flavour and aroma.

We have dedicated a machine solely to the production of the specialty coffees, to offer a particularly refined coffee for connoisseurs.